Lorem ipsum dolor sit amet, consectetur adipiscing elit.

We are glad that you chose one of our products

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

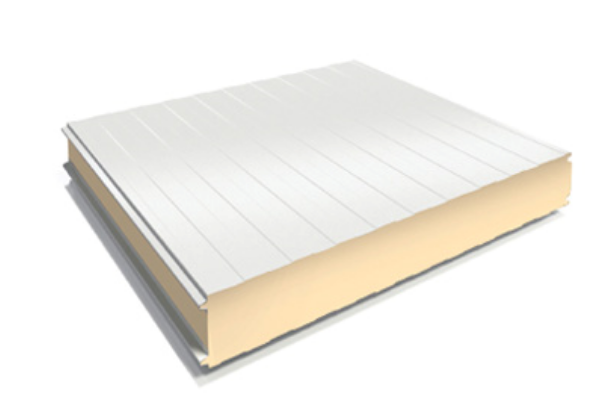

Mega Metal Factory’s specialized in production, sales and export of Polyurethane (PU) & Polyisocyanurate (PIR) Insulated Sandwich Panel & Rockwool. Sandwich Panels are produced in a continue line with 3 types of insulation materials including such as, Polyurethane (PUR), Polyisocyanurate (PIR) & Rockwool insulation thicknesses. As external and internal surfaces of sandwich panel painted galvanized

They are manufactured as polyester, plastisol, PVDF and food safe painted according to the needs of the Project. They can be manufactured in all RAL codes. Panel Tech’s Insulated Roof and Wall Sandwich Panels are responding all needs such as thermal insulation, air tightness, hygiene, aesthetics, and fire insulation. Acoustic insulated Roof and Wall Panels for sound insulation Wall Panel for container and prefabricated buildings and Cold Room Panels for cold storages.

Some of the benefits of using Mega Metal Factory’s sandwich panels are:

– Excellent thermal insulation. Thermal conductivity of panels with polyisocyanurate foam core is λ = 0,022 W/m*K.

– Excellent protection against weather conditions, maintaining properties and appearance for many years. When coating is properly selected according to local conditions, several years’ durability of panels can be reached without any problem.

– Complete seal against precipitations, snow and dampness. Perfectly finished joints ensure complete waterproofness for many years, if installation standards are followed.

– Sound absorption. Properly selected core material can give perfect noise insulation parameters. They are particularly important if insulation of outside noise, reduction of industrial noise propagation to the outside of the building or noise reduction within the building is required.

– Fire resistance properties according to the needs. Using proper type of core can ensure the fire resistance. This enables protection of escape routes and separation of fire compartments from each other.

– Easy and quick installation, low construction costs. As a result, lower operating costs over the years. A 50mm thick PU/PIR foam panel has the same heat-transfer coefficient U as a 75 cm thick aerated concrete wall, 60 cm thick structural clay tile wall or a 190 cm thick brick wall.

– Good strength parameters. Roof panels can withstand the load of snow and wind depending on their thickness and climatic zone, with supports’ span of more than 3 m. In most cases, wall panels can be used with supports’ span of up to 6 m. This results in real savings in terms of the supporting structure, and thus overall costs of the entire building.

– We have managed to combine all the above benefits to the user with benefits to the natural environment. Total power input in the production of the material used for thermal insulation of the building, on average, pays for itself after two or three years from installation. Materials used in production are recyclable. Steel can be easily reused. Waste core materials can also be recycled, while production of the panels itself is not harmful to the environment.

Mega Metal Factory’s specialized in production, sales and export of Polyurethane (PU) & Polyisocyanurate (PIR) Insulated Sandwich Panel & Rockwool. Sandwich Panels are produced in a continue line with 3 types of insulation materials including such as, Polyurethane (PUR), Polyisocyanurate (PIR) & Rockwool insulation thicknesses. As external and internal surfaces of sandwich panel painted galvanized

They are manufactured as polyester, plastisol, PVDF and food safe painted according to the needs of the Project. They can be manufactured in all RAL codes. Panel Tech’s Insulated Roof and Wall Sandwich Panels are responding all needs such as thermal insulation, air tightness, hygiene, aesthetics, and fire insulation. Acoustic insulated Roof and Wall Panels for sound insulation Wall Panel for container and prefabricated buildings and Cold Room Panels for cold storages.

Some of the benefits of using Mega Metal Factory’s sandwich panels are:

– Excellent thermal insulation. Thermal conductivity of panels with polyisocyanurate foam core is λ = 0,022 W/m*K.

– Excellent protection against weather conditions, maintaining properties and appearance for many years. When coating is properly selected according to local conditions, several years’ durability of panels can be reached without any problem.

– Complete seal against precipitations, snow and dampness. Perfectly finished joints ensure complete waterproofness for many years, if installation standards are followed.

– Sound absorption. Properly selected core material can give perfect noise insulation parameters. They are particularly important if insulation of outside noise, reduction of industrial noise propagation to the outside of the building or noise reduction within the building is required.

– Fire resistance properties according to the needs. Using proper type of core can ensure the fire resistance. This enables protection of escape routes and separation of fire compartments from each other.

– Easy and quick installation, low construction costs. As a result, lower operating costs over the years. A 50mm thick PU/PIR foam panel has the same heat-transfer coefficient U as a 75 cm thick aerated concrete wall, 60 cm thick structural clay tile wall or a 190 cm thick brick wall.

– Good strength parameters. Roof panels can withstand the load of snow and wind depending on their thickness and climatic zone, with supports’ span of more than 3 m. In most cases, wall panels can be used with supports’ span of up to 6 m. This results in real savings in terms of the supporting structure, and thus overall costs of the entire building.

– We have managed to combine all the above benefits to the user with benefits to the natural environment. Total power input in the production of the material used for thermal insulation of the building, on average, pays for itself after two or three years from installation. Materials used in production are recyclable. Steel can be easily reused. Waste core materials can also be recycled, while production of the panels itself is not harmful to the environment.

Mega Metal factory w.l.l is considered as one of the leading manufacturersof corrugated sheet , Sandwich Panels, Profile Sheet & expanded metal sheet, fencing net , barbed wire , throughout the State of Qatar.

Working closely with our customers, we provide advice for the best solution for each project.

All rights reserved © - 2025 Mega Metal